About Company

- Home

- About Company

Welcome To Helli Moulds

At Helli Moulds, we are specialized in the areas of innovative solutions for Mould Manufacturing based on our theme “We Shape Your Ease” With strong focus on customer delight we are Specialized in Manufacturing Moulds for the Automotive, Logistics, Toy and Home Appliance divisions. Our commitment to innovation and quality ensures that our clients receive tailored solutions that elevate their manufacturing processes. Trust Helli Moulds for cutting-edge technology and unparalleled expertise in the world of mould manufacturing.

Customer-Centric Approach

Your success is our priority. We work closely with our clients to understand their unique needs and provide tailored mould solutions that drive their success.

Expertise Across Industries

Extensive expertise across diverse industries, providing comprehensive and innovative mould solutions ensuring tailored and efficient solutions for various manufacturing needs.

Precision Engineering

Our moulds are a treatment to precision engineering, ensuring that each product meets the highest standards of accuracy and durability.

Quality Assurance

Committed to delivering top-notch quality, HelliMoulds employees rigorous quality control measures throughout the manufacturing process, guaranteeing precision and reliability.

We're always leading. Always researching. Always testing.

we consistently lead through relentless research and continuous testing. Our commitment is unwavering, driving innovation at every turn. We’re dedicated to setting new industry standards, ensuring our automotive molds stay ahead, delivering cutting-edge solutions that redefine excellence and reliability in manufacturing.

Customer satisfaction

Experienced Technicians

Professional Expert

Milestone

OUR BEGINNING

HELLI MOULD STARTED TO MAKE MOULD FOR

Luggage Industry

HELLI MOULD STARTED TO MAKE MOULD FOR

Piping Industry

Toy Industry

Helli Moulds started

Helli Moulds started

Our Beginning

Helli Mould started to make Mould for

Medical Industry

Luggage Industry

Helli Moulds started to make Moulds for

Piping Industry

Toy Industry

Helli Moulds started

Helli Moulds started

Future Plan

Presentations are tools that can be used as lectures, speeches, reports, and more.

In the future, our automotive mould solution aims to revolutionize manufacturing efficiency, incorporating advanced materials and precision engineering. Emphasizing sustainability, we’ll integrate smart technologies for real-time monitoring, reducing waste, and enhancing production speed. Our goal is to be at the forefront of innovation, driving the automotive industry into a sustainable and high-performance future.

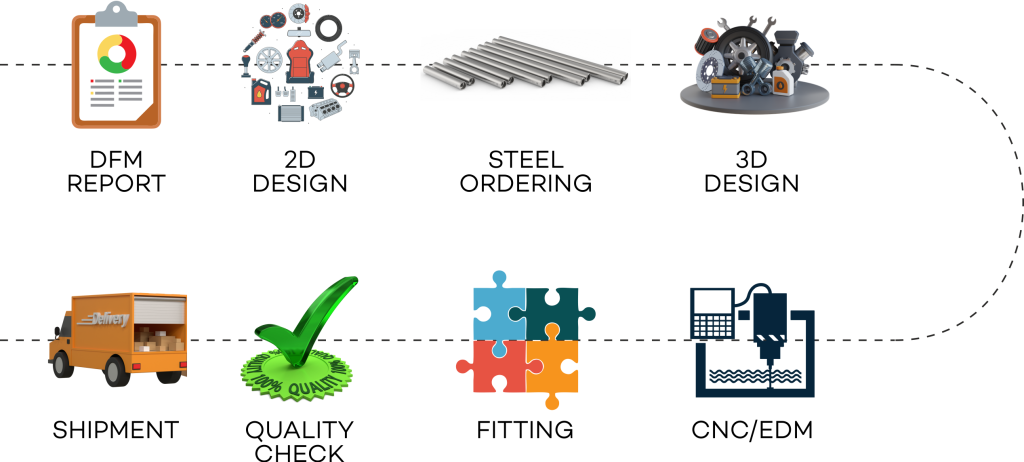

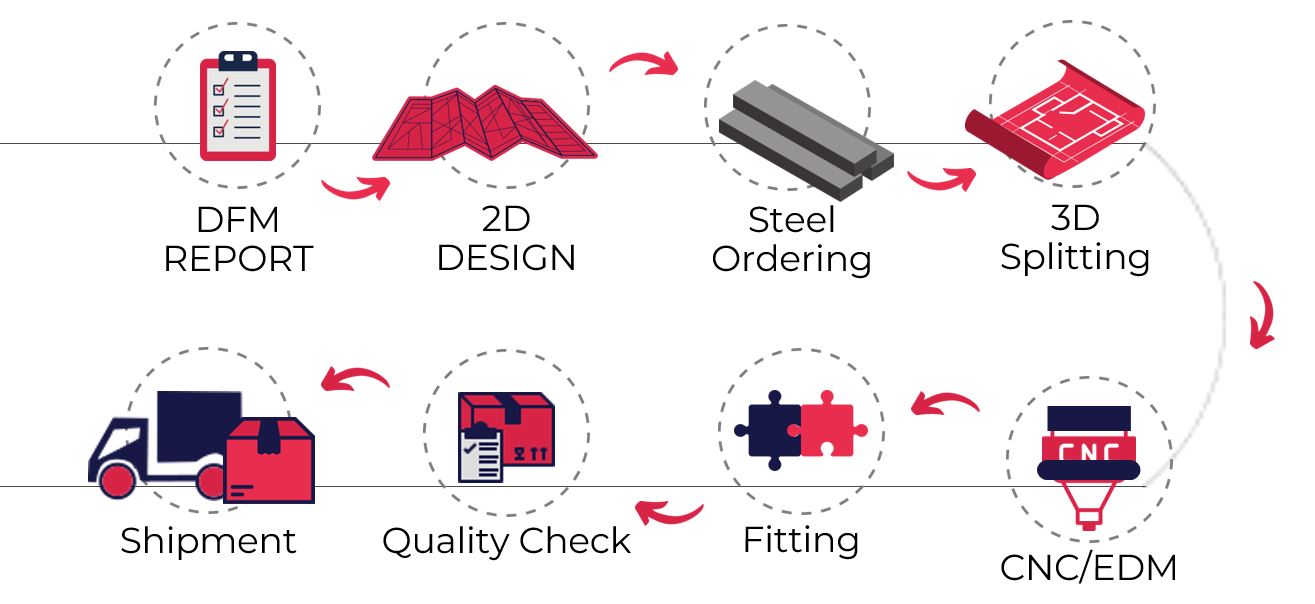

The Process We Follow-

At HeliiMoulds we follow the step monitored and international standard process in our manufacturing facilities –

- User Need

- Requirement Analysis

- Efficient Manufacturing

- Planing & Designing

- Precision Engineering

- Quality Assurance

WORKFLOW

FAQ'S

Ans: Approximately 16-20 Moulds.

Up to 250T – 20no.s

300T – 650T – 16no.s

650T – 1200T – 8no.s

1200T – 1600T – 2no.s

Ans: 120 Plus

Ans: We have overhead crane capacity of 15 Ton and we can make

Moulds which can go in 1600 Ton Injection Molding Machine.

Ans: Below mentioned software’s are used.

a. UG-NX12 with Mold Wizard

b. NX Drafting

c. DELCAM

d .Mould flow – External Support

Ans: Yes, we have and all the gauges and precise measuring instruments are available.

Ans: a) 15 TON Over head crane & 4 no.of Independent crane with 3 Ton Capacity for Assembly cell

b) Portable Cooling & Hydraulic Checking unit

Ans: Up to 660T Machine available in house. Above 660T available at nearby facility.